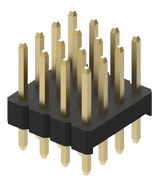

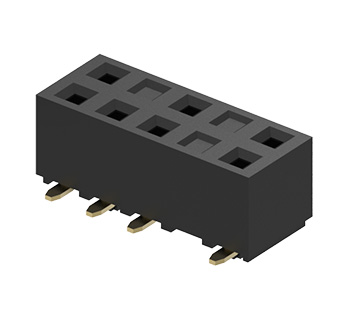

Board to board connectors

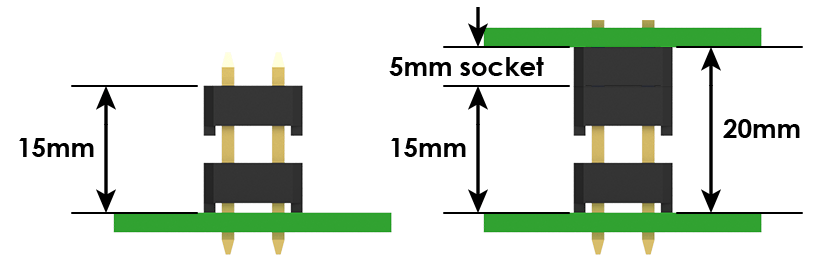

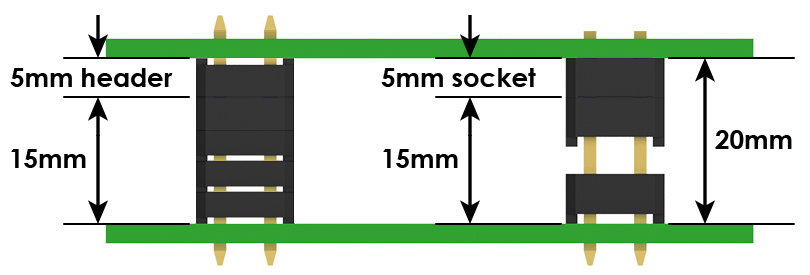

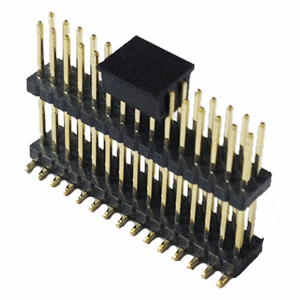

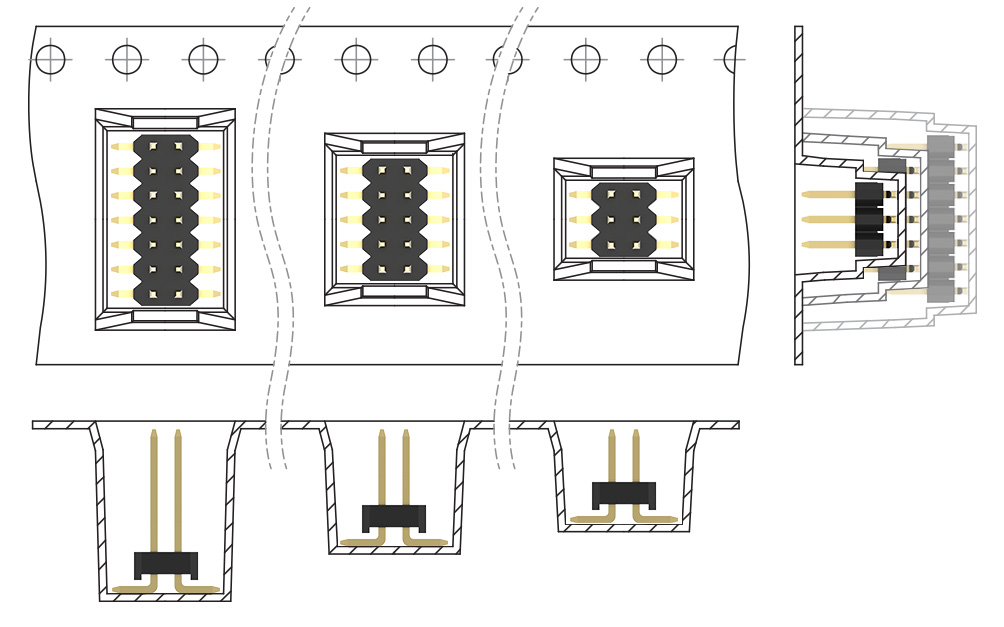

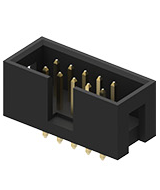

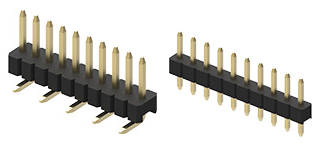

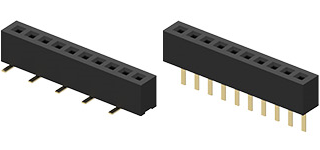

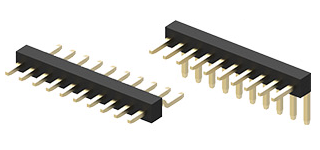

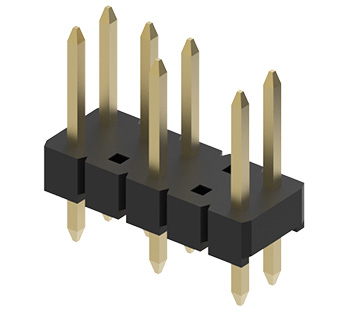

High quality and competitively priced PCB connectors for any situation. With over 160 standard parts in the GCT Board to board range and a large element of customisation also available. Pitches ranging from 0.8mm to 5.08mm, selectable pin lengths, and insulator heights. Other features include locating peg options, shrouding, polarisation, keyed or elevated headers and sockets, with completely bespoke solutions possible.

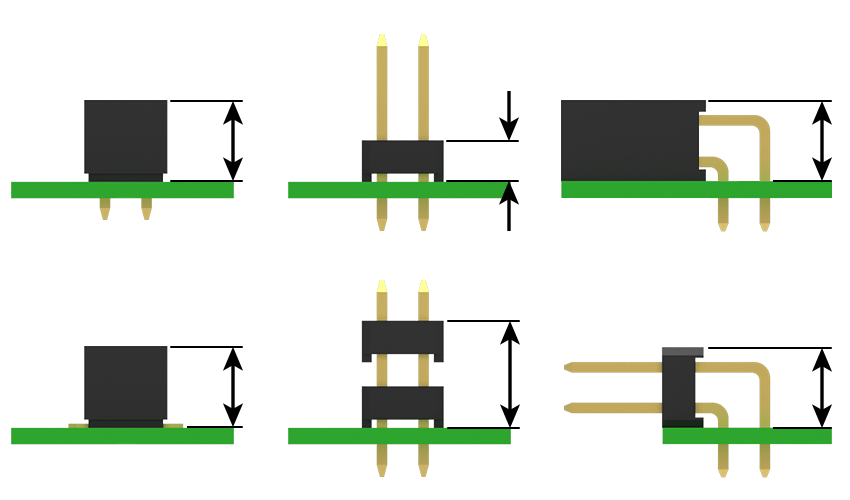

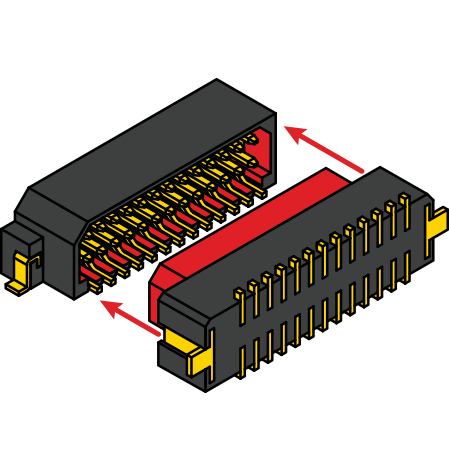

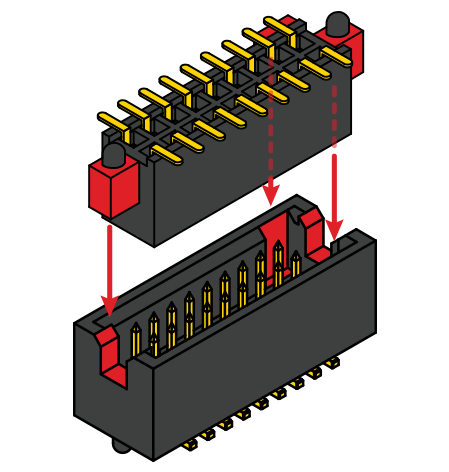

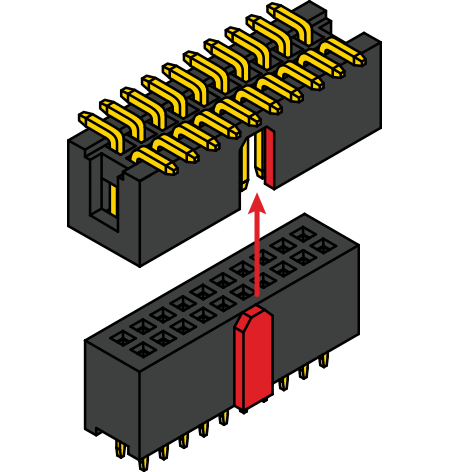

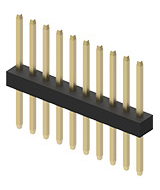

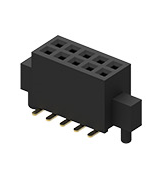

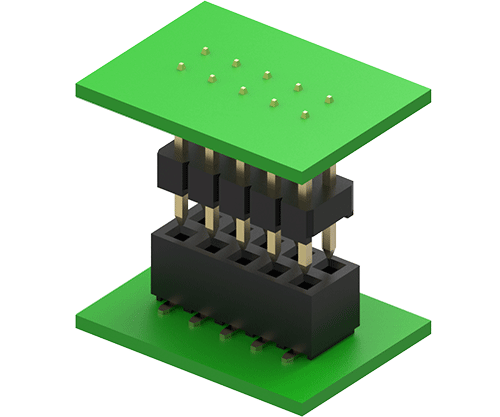

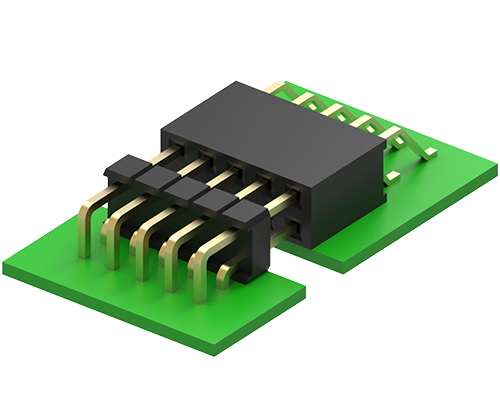

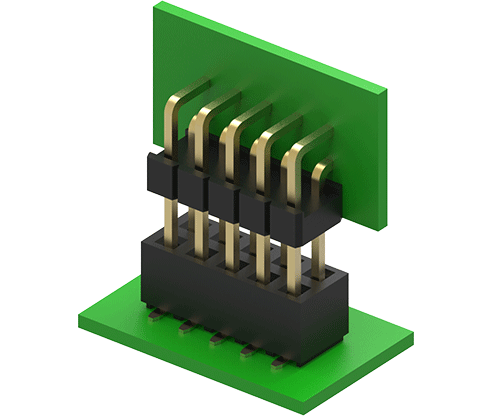

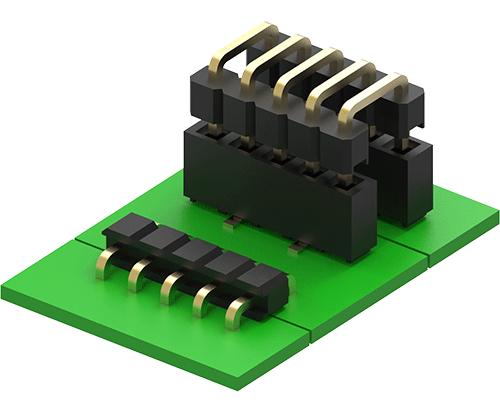

Board to board connectors are designed to connect printed circuit boards together without a cable. This connection can be permanent in the case of "hard soldering" (soldering a pin header to the PCB at both ends). This approach may be used in a "fit and forget" solution where no mating cycles are required.

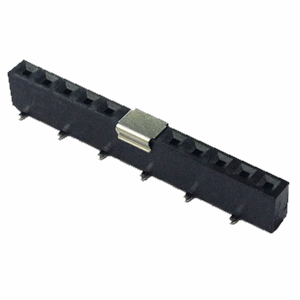

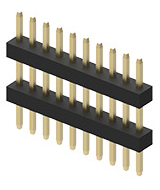

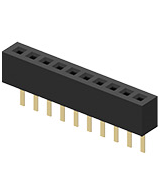

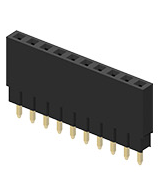

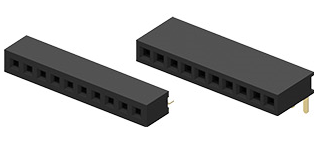

However, in most applications the printed circuit boards are required to be connected and disconnected to simplify assembly and allow design flexibility. Pin headers (male) and socket (female) connectors are used as a

pair, one mating and unmating is described as a "mating cycle".

Be in the know about product launches, promotions and more

Useful

Support

Global headquarters

Regional offices

Copyright © 2024 GCT (Global Connector Technology) All Rights Reserved

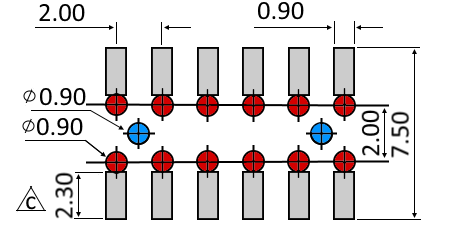

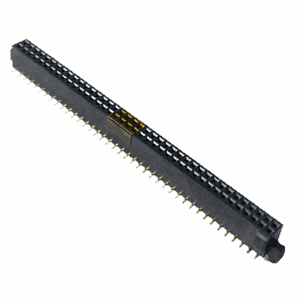

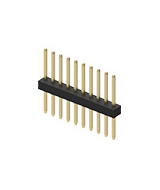

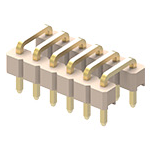

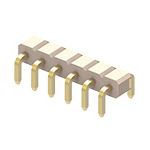

Larger pitches can be created by selective loading (i.e. a

Larger pitches can be created by selective loading (i.e. a

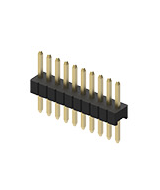

As with the voided pin but with reference to sockets (also known as voided contact or polarization).

As with the voided pin but with reference to sockets (also known as voided contact or polarization).